STEP LOGIC in the overview of Domestic Integrators in the DPC Market

The domestic Data Processing Centre (DPC) market continues to grow. Meanwhile, competition between players is growing and customer requirements are being strengthened. Vadim Kalle, Deputy Head of Engineering Design Department at STEP LOGIC, answered the ICT-Online’s questions about the current development of the sector, underlying innovations and legislative initiatives for this process, risks related to construction of data processing centres in Russia, and solution to energy consumption problems.

Vadim Kalle, Deputy Head of Engineering Design Department at STEP LOGIC

How is the DPC market developing now? Are there any fundamental new trends?

The DPC market is growing: many new objects, both corporate and commercial, are emerging. Such factors as organic data growth (according to IDC forecasts, the amount of data in the world will have reached 40 trillion GB by 2020, i.e. 5,200 GB of data per capita) and legislative initiatives requiring additional computational powers (No. 242-FZ, the package by Yarovaya), considerably stimulate active development of the market.

At the same time, after the crisis of 2014–2015, customers began to treat costs more thoughtfully, therefore, almost every new project has requirements for CAPEX optimization. Often, for the same reason, the projects use equipment from manufacturers that have not achieved a strong position in the Russian market yet. Domestic manufacturers of climatic and precision equipment are emerging.

Unlike Western countries, the current Russian DPC market does not experience a massive transition to green technologies. The reason again lies in the financial aspect. As a rule, the customer wants its expenses to be paid off in 3–5 years. However, it is impossible under the present conditions: given cheap electric power, investment in green technologies is too high.

Is it easier or harder to work in this market than before and why? What unique competences do integrators need today to survive in this market?

Surely, it becomes harder to work in this market over the course of time. The Russian DPC market is competitively saturated: many companies are offering services for the construction, modernization and operation of data processing centres. Most of them have effective partnership with vendors, they know where it is cheaper to buy particular equipment. Therefore, when choosing a contractor, customers assess both the relevant experience and the maximum elaboration of the project at the stages of the technical and commercial proposals and requirements specifications. Additional preferences that they will receive when working with a specific integrator also important. They may include special services, e.g. 3D modelling, project visualization at the initial stage.

As for the competitive advantages of STEP LOGIC, we provide a full range of services related to the design and construction of engineering infrastructure, the use of BIM technology, 3D and CFD-modelling. In addition, we use in our projects BIM+Enscape and BIM+Live in order to ensure modelling and artistic visualization of various objects from fragments of engineering systems to entire neighbourhoods with realistic landscapes, which makes it possible to move inside our 3D models in real time in virtual reality. The use of these technologies is accompanied by a high degree of business processes automation, transparency of interaction schemes and the maximum degree of responsibility of the process participants at all stages of the object's life cycle. Our other competitive advantage is a technical support centre, which has been providing technical support for projects for more than 20 years and offers customers service and repair of high-tech equipment from the leading world and domestic manufacturers.

One of our development areas is building energy modelling (BEM). It involves assessment of the integrated energy efficiency of all engineering systems, design solutions, the location of the building in space, etc. Due to special engineering calculations, it is possible to estimate the energy consumption of the object during the year and to predict the payback of design solutions. Today, BEM is a standard in Europe.

Please specify the problems and risks of DPC construction in Russia?

I would like to focus on three main issues. Firstly, this is the culture of construction, whose level is low in our country due to a number of historical reasons. We should remember that all stages of DPC construction from site selection and pre-design surveys to the organization of the construction process require careful study, specific skills, drawing-up of relevant documentation, etc. Therefore, it is so important to choose a qualified contractor who has the skills to manage a complex infrastructure project.

Secondly, this is the lack of regulations and guidelines on the construction of data processing centres in the Russian Federation. Development of national standards would greatly facilitate the work of IT companies, make it more transparent and have a significant impact on the development of the DPC market.

And finally, as a data processing centre is a cost-intensive facility, I think that the lack of sufficient investment in this area and sometimes the pursuit of inappropriate savings constitute an important problem in the construction of the DPC. For example, a customer may design a technical solution with one company, and implement it with another company using equipment not stipulated by the project. This path has many pitfalls: specialists of a company that was not engaged in the design may fail to understand the details or may lack the appropriate technological resources and competencies, and finally, may carry out incorrect designer supervision. All these factors may lead to problems during the implementation and to going beyond the budget: the project will have to be redone, unforeseen expenses will appear.

Please share your experience in the sphere of significant reduction of power consumption by a DPC?

One of the most effective technologies for the cooling system of a DPC, which makes it possible to significantly reduce energy consumption and reduce the cost of maintaining the system itself, is free cooling. The majority of industry vendors produce such solutions — APC by Schneider Electric, Vertiv, STULZ, etc.

The KyotoCooling system is not the most common system but it has been already implemented in some data processing centres in the Russian Federation. This is a green technology that uses the inlet cold air all year round to cool the DPC. Backup vapor-compression machines are used to ensure the required reliability of such systems, but the performance of the cooling system is provided by the environment with minimal power consumption. At the same time, the average annual PUE (Power Usage Effectiveness) of the entire DPC decreases from 1.3...1.25 for systems based on water cooling to 1.15 for KyotoCooling systems

Besides, some technologies use exhaust heat to generate cold. STEP LOGIC is working on one of such projects. The system operates as follows: Absorption chillers are installed in cooling units of the DPC. They use the heat coming from a source located in the immediate vicinity of the data processing centre, e.g. a thermal power plant or a plant.

The generation of cold occurs in a special cycle of water evaporation in vacuum and absorption in a lithium bromide solution, which is then regenerated using an external heat source. The PUE value for this scheme is also at 1.15. However, the payback of such solutions starts from 7–8 years at current prices for electricity.

Tell us please about the most interesting project related to the construction or operation of a DPC?

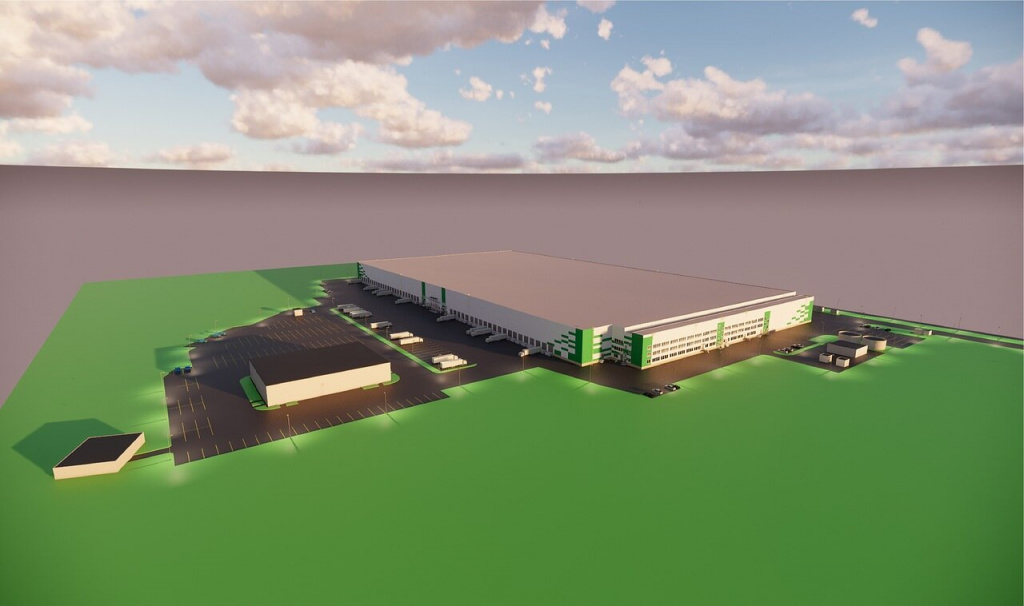

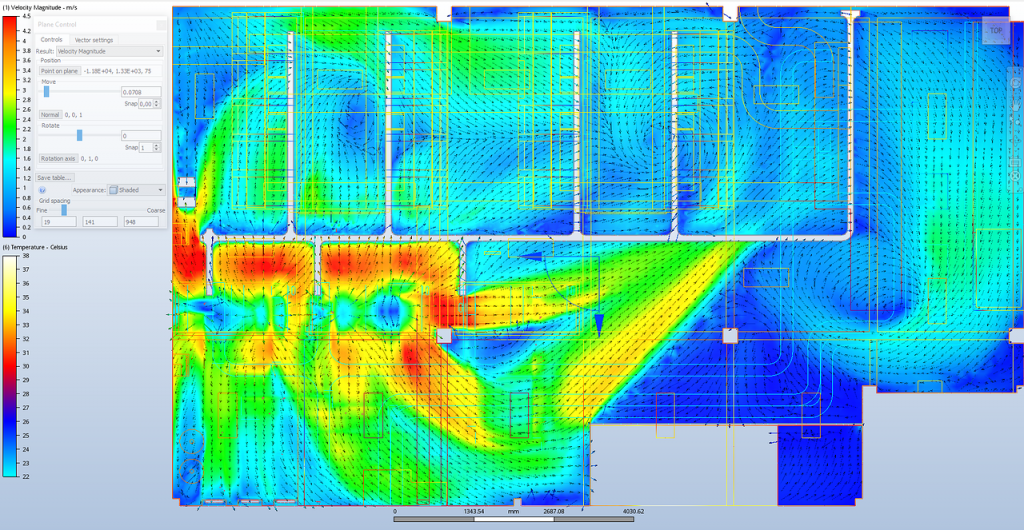

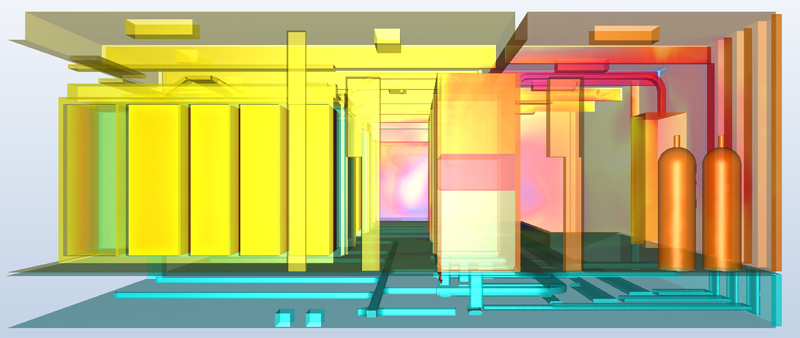

One of the recent large-scale and interesting projects implemented by us was the modelling and simulation of thermal processes for a large logistics centre. We have used BIM to design the engineering infrastructure for a data processing centre, a warehousing complex and buildings adjacent to it, we also modelled the buildings using the documentation we received from the architects. The utility systems also included air conditioning and ventilation, power supply circuits, a structured cabling system, CCTV and security systems and a gaseous fire suppression system.

One important task we performed using CFD was ensuring the right range of temperatures maintained in the data processing centre; this was done by simulating the operation of the centre under the design load and selecting the optimal configuration for the partitions to divide up the cold and hot corridors as well as to set up the meshes in the raised floor.

What are your forecasts for the development of the domestic DPC market?

The rapid digitalization that has engulfed all sectors of the economy is the growth driver for the market of corporate and Collocation DPC. IoT, IIoT, 5G technologies allow connecting a huge number of devices, information from which should be collected, stored, processed and analysed. All of these things will require additional computing power and will lead to rapid growth in the number of data processing centres in our country.