UPS to protect systems. And what protects UPS?

Typically, in medium- and large-size data processing centers, separate rooms are allocated for uninterruptible power supplies (UPS). They are critical for the operation of all IT and engineering systems and require the proper organisation and maintenance of the microclimate. In this article, with a specific example, we will show how to use the technology of computational modelling of thermodynamic processes (Computational Fluid Dynamics, CFD) to predict the operation of an air conditioning system, and give basic recommendations for UPS rooms.

Vadim Kalle,Deputy Head of the Engineering Systems Department at STEP LOGIC

Consider a project, in which it was necessary to perform CFD modelling of the air conditioning system of a non-standard UPS room and get practical recommendations for improving its operation. An uninterrupted power supply equipment with a total capacity of 2.5 MW is installed in the room. To remove heat surpluses that occur during the operation of the switchboard equipment, UPS, their cyclic charging and discharging, an air conditioning system based on cabinet-type water conditioners has been designed at the facility. In total, the room is equipped with five air conditioners (four operating and one standby).

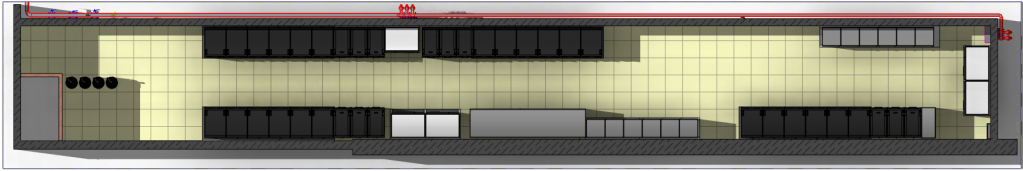

Fig. 1. Room visualisation

The room is "difficult" in terms of air conditioning due to a number of factors:

- The dimension ratio of the facility — 3 m in width with a length of 40 m.

- The combination of thermal loads. Unlike server racks with their high power density, large temperature drop and relatively small air flow rate, there are substantial air flow rates with a small temperature drop (ΔT) on the UPS due to the built-in cooling fans (i.e. forced convection), as well as heat transfer from the switchboard equipment due to free convection. That is, two basic types of heat removal from the equipment are combined in the same room. The design thermal load is 150 kW, i.e. about 310 W/m3 with an air exchange rate of about 125 l/h.

- Non-standard layout of air conditioners. The equipment layout was related to the technological requirements of the customer. Conditioning under the raised floor was not considered: it was necessary to make a minimum raised floor to level it up with the floor level outside the room.

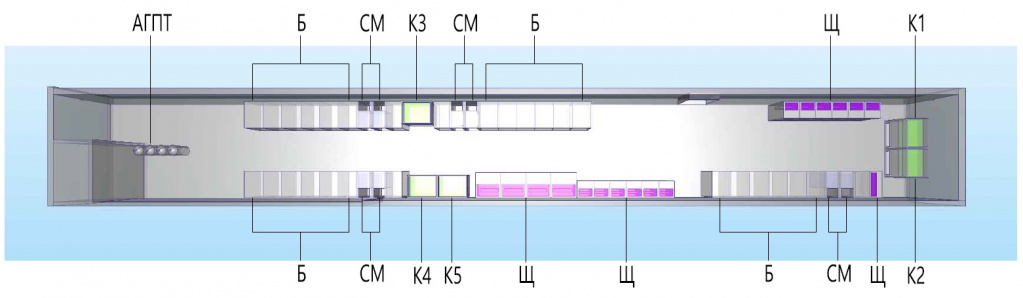

Fig. 2. Layout diagram for the equipment in the room

In contrast to the DPC, for UPS rooms, either household or "semi-industrial" ceiling and duct-type air conditioners are still used, which are not designed for 24/7 year-round operation. However, the main mistake is that ΔT on these air conditioners is much higher than that on the UPS cabinets. In fact, the balance of power in the volume of the room matches, however, the balance of air flow rate does not match. Insufficient air exchange can cause overheating of the equipment. Unfortunately, this important point is often missed in the calculations. But this is the fundamental difference between air conditioning systems for UPS rooms and server rooms and DPC with high power density. Therefore, it is necessary to use a precision air conditioning system in UPS rooms, that makes it possible to adjust the operating temperature and air flow rates in a wide range.

In the CFD model created by us (Figure 3) the following heat generating objects were specified: UPS power modules (PM), distribution and parallel operation switchboards (S). Additional heat gains from the battery cabinets (B), lighting, ventilation, thermal conductivity of the walls were not taken into account due to the small effect on the result.

Various schemes of switching on air conditioners (K1–K5), which are in rotation, and also switching on all air conditioners at the same time were modelled.

Fig. 3. Layout diagram for the equipment in CFD model

Main characteristics of the design model:

- Mode: Steady State;

- Turbulence model: k-epsilon;

- Advection diagram: Modified Petrov-Galerkin;

- Number of design nodes: 1.74 million;

- Number of design volume elements: 6.28 million.

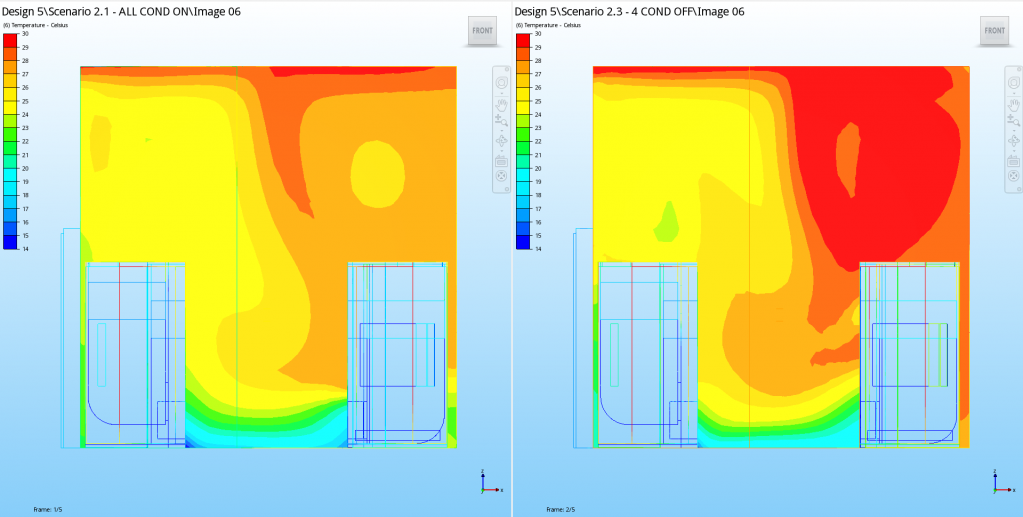

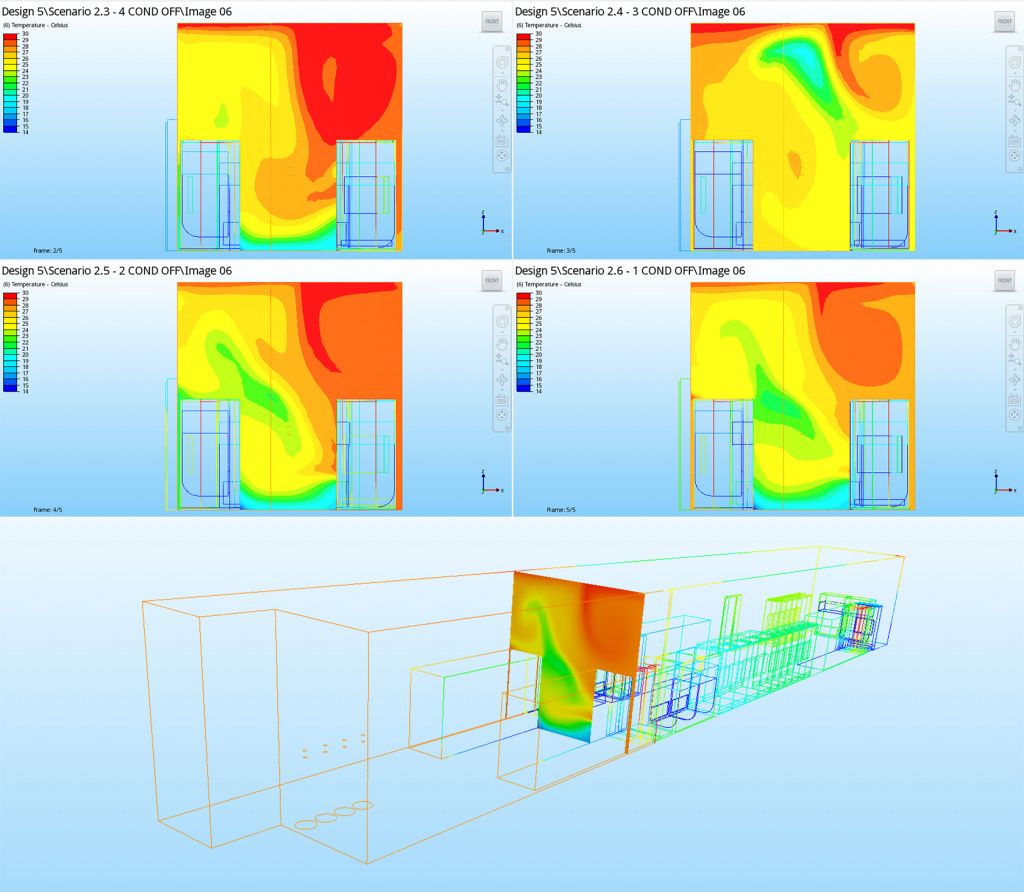

- Stagnant zones with raised temperatures in the area of installation of the UPS and battery modules occur in any of the options for switching on air conditioners during rotation.

- With simultaneous operation of all air conditioners, the maximum temperature in the installation area of the UPS and battery modules does not exceed +27 °C, which is permissible.

- When four of five air conditioners are operating, the maximum temperature in the installation area of the UPS and battery modules can reach +29 °C, which is normal for the power part of the UPS, but for VRLA batteries it becomes critical with a possible 30% reduction in their service life.

- The instability of cooling the switchboard equipment without forced ventilation is present if the switchboards are installed in the same place as the UPS power equipment. This is due to the significant influence of the main flow of the air conditioning system on the air exhaust through the ventilation grilles of the switchboards. At the same time, in the lower area of the switchboards, an ejection effect may occur on the ventilation grilles, and the heated air does not come out of the upper ventilation grilles of the switchboards, but on the contrary moves inside the switchboard heating it. CFD model of the switchboard with forced ventilation demonstrates good performance in the heat removal and provides a sustainable solution to the problem.

- When designing an air conditioning system for rooms with a complex configuration in combination with a high thermal load, the CFD modelling is required.

- When calculating air conditioning systems, it is necessary to pay attention not only to the balance of power, but also to the balance of air flow rate.

- It is necessary to use precision air conditioners that make it possible to flexibly adjust both the air flow rate and ΔT.

- It is recommended to use the "hot reserve" mode of operation, when all air conditioners operate at reduced power. The "cold reserve" mode, in which several air conditioners operate and the standby ones are switched off, increases the probability of overheating zones.

- It is recommended to use switchboard equipment with forced ventilation for guaranteed heat removal.

- For switchboard equipment without forced ventilation, heat transfer through the body walls must be taken into account in addition to the main heat removal through the ventilation grilles. In the presence of forced ventilation, the heat removal through the walls may be neglected to simplify the solution.

During the CFD modelling, the following results were obtained:

We would like to pay attention to the modelling of switchboards and power cabinets that generate heat. For such equipment, it is impossible to directly convert geometry from 3D model to CFD model with all circuit breakers and busbars, fasteners: there is a large number of small elements that do not affect the result, but complicate the model, and it is impossible to correctly set the thermal load. Therefore, we used a design model consisting of a cabinet body, an equivalent heat generator in the cabinet and a ventilation device that cools the cabinet. As a result, we got a stable design diagram.

When analysing (interpreting) the results of CFD modelling, various visualisation tools were used: sections, iso surfaces, iso volumes and traces. All of them clearly demonstrate, how the air is distributed in the room, what equipment configuration will be optimal, and also make it possible to see overheating and stagnant zones. Based on the data obtained, a list of recommendations for improving the performance of the air conditioning system was formed.

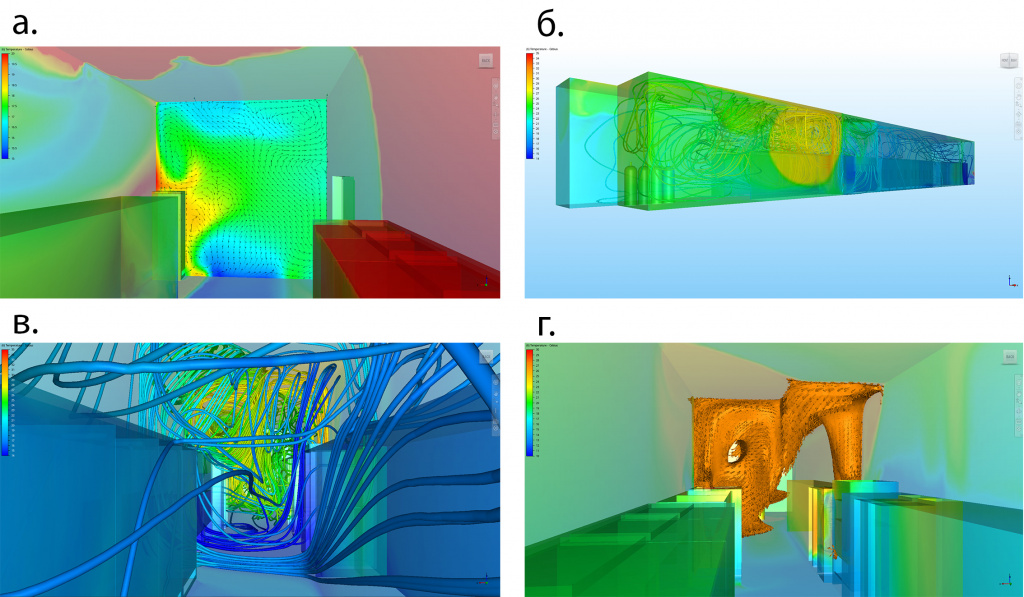

Fig. 4. Examples of visualisation of calculation results in CFD. Comparison of the operation modes of air conditioners in the Decision Center: on the left — all air conditioners are switched on, on the right — air conditioner No. 4 is switched off

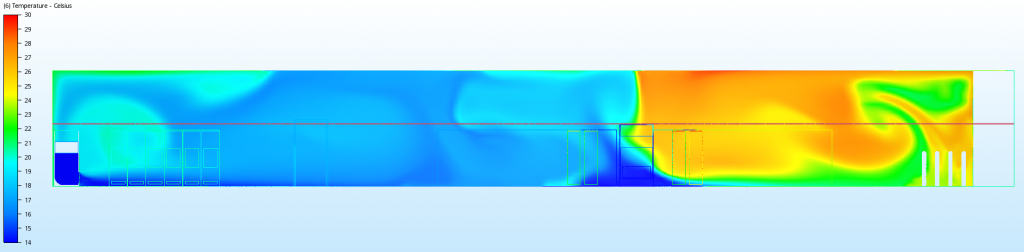

Fig. 5. Examples of visualisation of calculation results in CFD. Comparison of four modes of rotation of air conditioners in the Decision Center

Fig. 6. Examples of visualisation of calculation results in CFD.

a — temperature distribution in the vertical section (planes) with projection of the velocity vectors; b, c — current traces; d — iso volume with a temperature of +27 °C

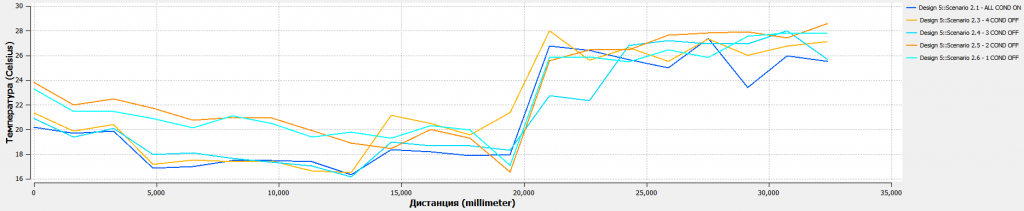

Fig. 7. Graphs of temperature distribution in the center of the "cold" corridor at el. 2.2 m from the raised floor level, all operating modes of the air conditioning system

Practical recommendations for the organisation of air conditioning systems for UPS rooms: